In the realm of manufacturing and engineering, the concept of a precision machine shop plays a pivotal role in delivering high-quality, intricately crafted components. A precision machine shop refers to a specialized facility that utilizes advanced tools and technology to produce parts with exceptionally tight tolerances and superior finish. As Mark Thompson, a renowned expert in precision machining, aptly stated, "In a precision machine shop, every detail matters; it's the difference between just fitting and being perfectly aligned." This level of precision is crucial in various industries, from aerospace to medical devices, where even the smallest deviation can lead to significant consequences.

The benefits of collaborating with a precision machine shop extend beyond mere accuracy. These shops employ skilled machinists and state-of-the-art equipment, enabling them to tackle complex projects that demand not only precision but also efficiency. By integrating the latest CNC machining technologies and quality control protocols, precision machine shops enhance productivity and reduce waste, ultimately delivering projects on time and within budget. As we delve deeper into the intricacies of precision machining, we will explore how these specialized facilities can significantly elevate the quality and reliability of your projects, setting the stage for success in today's competitive landscape.

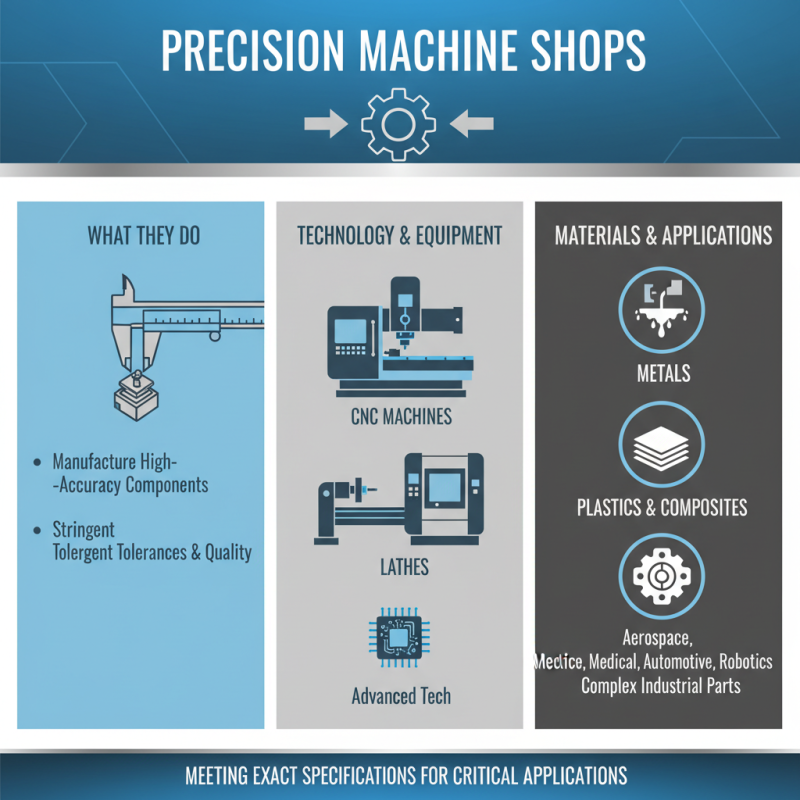

Precision machine shops specialize in the manufacturing of components that require high accuracy and stringent tolerances. These facilities utilize advanced machinery and technology such as CNC (Computer Numerical Control) machines, lathes, and milling machines to create parts from various materials, including metals, plastics, and composites. The primary goal of a precision machine shop is to produce intricate components that meet exact specifications, ensuring compatibility and functionality in their intended applications.

The capabilities of precision machine shops extend across various industries, including aerospace, automotive, medical, and electronics. By employing skilled machinists and engineers, these shops can offer not only high-quality manufacturing but also design support and prototyping services. This collaborative approach enhances the efficiency of projects by minimizing errors and reducing lead times. As precision machining becomes increasingly vital in modern manufacturing, choosing the right machine shop can significantly impact a project's success, providing the required accuracy and reliability that many industries demand.

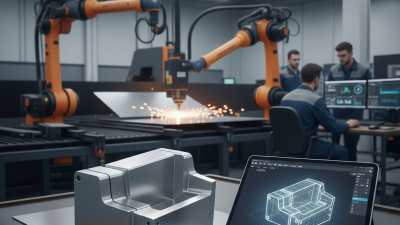

Precision machining is a highly specialized process that utilizes advanced technologies to produce components with extremely tight tolerances and exceptional surface finishes. Key technologies involved in precision machining include Computer Numerical Control (CNC) machining, which employs computers to automate the control of machine tools, allowing for intricate designs and high repeatability. This technology is essential in applications where consistency is crucial, as it can produce thousands of identical parts with minimal variance.

Another critical technology in precision machining is Electrical Discharge Machining (EDM). This process uses electrical discharges to remove material from a workpiece, making it highly effective for hard metals and complex geometries. EDM is particularly useful in industries requiring intricate shapes, such as aerospace and medical device manufacturing. Additionally, advancements in additive manufacturing techniques enable the creation of complex structures layer by layer, further expanding the possibilities within precision machining.

Together, these technologies not only enhance the efficiency and accuracy of production but also open up new avenues for innovation in product design. By leveraging these advanced capabilities, precision machine shops can significantly contribute to the success of engineering projects, ensuring higher quality outcomes and reduced production times.

Precision machining plays a critical role across various industries by significantly enhancing product quality and operational efficiency. According to a report by the Precision Machined Products Association (PMPA), precision machining can improve component accuracy by up to 99.9%, which is vital in industries such as aerospace, automotive, and medical devices where tolerances are exceptionally tight. This high degree of precision results in better fitting parts, reduced waste, and improved performance in end products. For instance, components manufactured for the aerospace sector require meticulous attention to detail to withstand extreme environments, where even the slightest deviation can lead to catastrophic failures.

Furthermore, the adoption of advanced precision machining technologies, such as CNC machining and additive manufacturing, has revolutionized production processes. A report from SME (Society of Manufacturing Engineers) indicates that the use of CNC machines can increase production speed by up to 20% compared to traditional methods while maintaining high accuracy. This rapid prototyping ability allows companies to innovate quickly and respond to market changes more effectively. Industries like electronics also benefit from precision machining through the production of intricate components that are essential for modern devices, ensuring both functionality and efficiency in their designs.

Precision machine shops play a pivotal role in enhancing project efficiency and quality across various industries. By utilizing advanced machining technologies and techniques, these shops ensure that components are produced to exact specifications, minimizing errors and reducing waste. According to a report by the National Institute of Standards and Technology (NIST), implementing precision machining can lead to productivity increases of up to 30% in manufacturing processes. This not only shortens lead times but also allows companies to allocate resources more effectively, ensuring that critical projects adhere to tight schedules.

Moreover, precision machine shops are equipped to handle complex designs that require high precision and accuracy. A study conducted by the Precision Manufacturing Association indicates that projects utilizing precision machining see a 15% improvement in product quality, leading to higher customer satisfaction rates. This ability to deliver consistent quality allows companies to meet stringent industry standards and minimize the risks associated with product failures. By optimizing both the production process and final output, precision machine shops contribute significantly to the overall success of engineering and manufacturing projects.

When looking for a precision machine shop, it’s crucial to consider several key factors to ensure that your projects are completed efficiently and accurately. According to a report by the Precision Manufacturing Institute, precision machining plays a vital role in numerous industries, contributing nearly $46 billion to the U.S. economy alone. Understanding your specific needs will help you choose a shop that not only has the right capabilities but also the expertise in your particular field. Look for certifications such as ISO 9001, which indicate a commitment to quality management systems.

Tips: Always ask for a portfolio of past work to assess their experience with projects similar to yours. Additionally, inquiring about their machinery and technology can provide insights into their ability to meet your tolerances and timelines.

Another critical aspect to consider is the shop's customer service and communication. Your chosen precision machine shop should offer clear dialogue regarding project timelines, costs, and any potential challenges. A study conducted by the National Institute of Standards and Technology highlights that effective communication can reduce production errors by up to 25%. Be sure to discuss your project in detail and establish a rapport with the team to ensure that you are on the same page.

Tips: Consider scheduling a site visit to evaluate the shop's operations firsthand. This will allow you to gain confidence in their capabilities and safety measures before entering into a partnership.

You are using an outdated browser. Things may not appear as intended. We recommend updating your browser to the latest version.

Close