Plastic molding plays a crucial role in modern manufacturing processes. It involves shaping materials into specific forms. This technique is essential for producing various products efficiently.

The versatility of plastic molding allows for the creation of complex designs. Industries like automotive, consumer goods, and electronics benefit greatly. Yet, it also poses challenges. For instance, the quality of molds can vary. A slight imperfection in a mold can lead to flawed products.

Despite its advantages, not all manufacturers fully exploit plastic molding. Some still rely on traditional methods. This can result in higher costs and longer production times. Reflecting on these practices is vital for growth. Embracing plastic molding can enhance efficiency and innovation in the manufacturing landscape.

Plastic molding plays a crucial role in contemporary manufacturing techniques. It enables the efficient production of complex shapes and designs. Industries rely on plastic molding for its versatility and low-cost manufacturing capacity. Components that would be expensive or difficult to make using traditional methods are easily produced with plastic molding.

In many cases, manufacturers can create intricate parts in a single cycle. The process reduces waste, which is vital in today's eco-conscious world. However, not all manufacturers fully utilize this method. Some still lean toward older techniques that might not be as efficient. This can lead to higher costs and longer production times.

Customization is another area where plastic molding shines. It allows for rapid adjustments to designs. Despite its advantages, some companies resist adapting to this technology. They may fear initial investment costs or lack the necessary training. Reevaluating these fears could pave the way for more innovative practices in manufacturing today.

Plastic molding is essential in modern manufacturing. It encompasses various processes that shape materials into specific designs. Each method offers unique benefits and is chosen based on the application.

Injection molding is a popular technique. It involves injecting molten plastic into a mold. This process allows for complex shapes and high-volume production. Common applications include automotive parts, consumer goods, and medical devices. Some challenges remain, such as managing cycle times and mold design.

Extrusion molding is another key process. It shapes plastic into continuous profiles, ideal for pipes and sheets. The challenge here is ensuring uniformity in thickness. Compression molding is less common but useful for large items. It entails placing plastic in an open mold, then applying heat and pressure. Each method has strengths and weaknesses. Understanding these can lead to better manufacturing solutions.

Plastic molding plays a crucial role in modern manufacturing. This process enables the creation of various shapes and sizes with remarkable precision. It allows manufacturers to use different types of plastics. Each type offers unique properties and advantages. This versatility supports a wide range of applications, from automotive parts to consumer electronics.

One major advantage is cost efficiency. Plastic molding can produce complex parts quickly and in large quantities. This reduces production costs significantly. The high-speed production process minimizes waste, which is beneficial for both the environment and the bottom line. However, not every design is instantly achievable. Some intricate designs may require multiple iterations before becoming a viable option.

Another benefit is the ability to produce lightweight components. Lightweight parts enhance the efficiency of many products, especially in the automotive industry. Yet, achieving the perfect balance between strength and weight often demands careful engineering. Manufacturers need to continuously refine their methods. This balance is crucial for maintaining quality while promoting sustainability in manufacturing.

Plastic molding plays a crucial role in modern manufacturing. However, this technology faces many challenges. For example, ensuring the consistency of products can be tricky. Even small variations can lead to significant defects. Manufacturers must invest time in quality control to minimize this issue.

Innovations in plastic molding are exciting yet complex. Advanced materials and techniques are emerging. Some methods promise higher durability and better performance. However, these innovations often come with a price. Transitioning to new materials requires rethinking the entire production process. There is a risk involved that can deter some manufacturers from adopting these changes.

Environmental concerns also pose a challenge. The production and disposal of plastic create problems. As manufacturers push for efficiency, they need to consider sustainability. Striking a balance is no easy task. For now, the path of innovation in plastic molding must include thoughtful reflection on these issues.

The manufacturing industry is evolving rapidly, with plastic molding at its core. In 2022, the global plastic molding market was valued at approximately $200 billion. Projections suggest it could exceed $300 billion by 2030. This growth reflects a shift towards more efficient production methods and materials.

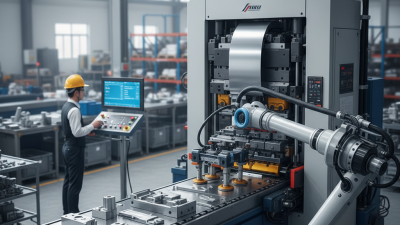

Future trends show increased automation in plastic molding. Technologies like robotic arms are enhancing precision. This automation aims to reduce waste and costs. However, challenges remain. The initial investment for advanced machinery can be significant. Small manufacturers might struggle to adapt.

Sustainability is another pressing issue. As pressure mounts to reduce plastic waste, innovations are emerging. Biodegradable plastics are gaining traction. However, they often come with performance trade-offs. Industry players must balance these factors. Finding the right materials will be crucial in the coming years.

This chart illustrates the projected growth of various plastic molding technologies in the manufacturing industry over the next five years.

You are using an outdated browser. Things may not appear as intended. We recommend updating your browser to the latest version.

Close