Mastering sheet metal work is an essential skill for anyone in the metal fabrication industry. Whether you are a beginner or an experienced professional, refining your techniques can lead to impressive results. The process involves more than just cutting and shaping metal; it requires an understanding of materials, tools, and methods.

Sheet metal work involves various techniques, including bending, welding, and assembling. Each technique presents unique challenges. For example, achieving precise bends without kinks demands patience and practice. Mistakes can happen, and learning from them is crucial. A simple miscalculation in measurements can lead to significant setbacks in the project.

Achieving professional results in sheet metal work takes dedication and a willingness to learn. Every project serves as an opportunity to improve skills. By embracing the complexities of this craft, you can turn challenges into stepping stones towards mastery. Develop your expertise, and soon your work will reflect your dedication to this art form.

Sheet metal work is an essential skill in various industries. Understanding the basics helps beginners to get started. The primary materials used in sheet metal work include aluminum, steel, and copper. Each material has unique properties that make it suitable for specific applications. For example, aluminum is lightweight and resistant to corrosion. Steel is strong and durable but can rust if not treated properly. Copper, known for its excellent conductivity, is often used in electrical applications.

There are different types of sheet metal, categorized mainly by thickness and material. The gauge of the metal is crucial. Thicker metal is more challenging to manipulate but offers greater strength. Thin sheets are easier to work with yet less robust. The choice of material and type depends on the project’s requirements. Sometimes, these choices lead to mistakes. A beginner may choose the wrong gauge, resulting in a weak structure.

Moreover, mastering techniques like cutting and bending takes practice. Beginners often struggle with achieving straight cuts or precise bends. It’s normal to experience challenges. Reflecting on mistakes helps improve skills over time. Understanding the materials and types is a vital step toward professional results in sheet metal work.

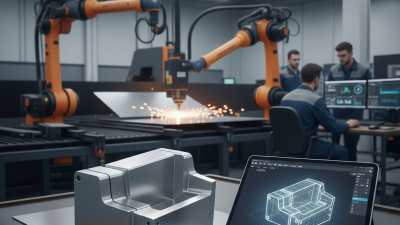

Sheet metal fabrication requires the right set of tools to achieve professional results. Essential tools include snips, shears, and brakes. Each tool serves a specific purpose and can make a significant difference in quality. According to industry reports, investing in high-quality tools can increase productivity by up to 30%.

Using the right tools also affects precision. For example, a metal brake allows for accurate bends, crucial for fitting pieces together seamlessly. Yet, many beginners overlook this. They might use improvised tools, leading to errors and rework. The frustration of scrapped materials affects efficiency.

Additionally, safety equipment is often neglected. Gloves and goggles are vital when working with sharp edges. Reports indicate that injuries in sheet metal work can be reduced by 50% with proper gear. However, some may feel invincible, risking their safety. Addressing these oversights is crucial for craftsmanship and long-term success.

Cutting sheet metal is an essential skill in metalworking. Many techniques exist, but not all yield perfect results. Knowing the right method can save time and reduce frustration. A commonly used technique is using tin snips. They are simple and effective. However, they can leave jagged edges. Sometimes, you may have to sand down the edges later.

Another method is using a metal shear. This tool provides clean cuts with minimal effort. It’s great for straight lines. However, it can be costly and may not be available for everyone. A hacksaw is an alternative, but it takes more time and effort. Precision is key, so taking the time to mark the cut line accurately is crucial.

Regardless of the technique, mistakes will happen. Cutting too short can lead to wasted material. Be patient with yourself. Each piece you cut teaches you something new. Reflect on what went wrong and how to improve. Mastering these techniques takes time and practice, but the results will be worth it.

Mastering advanced forming methods in sheet metal work is crucial for achieving professional results. Bending, rolling, and shaping are foundational techniques that influence the integrity and functionality of metal products. According to a recent industry report, precision in these processes can increase production efficiency by up to 30%. These improvements hinge on skilled execution and understanding of material properties.

Bending techniques, for example, often require knowledge of the material's yield strength. Miscalculations can lead to warping or insufficient bend radius. It's essential to select appropriate tooling that matches the sheet metal's specifications. A poorly executed bend can compromise the entire project. As reported, nearly 20% of defects in metal production stem from improper bending practices.

Rolling is another significant method that requires mastery. The process entails passing sheet metal through rolls to create curves or cylindrical shapes. A study indicates that the rolling process can reduce material waste by 15% when done correctly. Yet, getting the right thickness and tension is tricky. Many craftsmen overlook these factors, resulting in inconsistent quality.

Shaping techniques, including stretching and forming, require fine-tuned skills. One mistake can lead to unwanted distortions. It's worth considering that about 25% of all metal fabrications face issues linked to shaping mistakes. Continuous learning and adaptation to new techniques are vital for improvement in this field.

| Technique | Description | Application | Materials Used |

|---|---|---|---|

| Bending | A process to create a bend at specific angles using a press brake. | Used in creating brackets, enclosures, and structural components. | Aluminum, Steel, Stainless Steel |

| Rolling | Curving sheet metal into cylindrical shapes using rolling mills. | Commonly used in making pipes, tubes, and tanks. | Steel, Aluminum, Copper |

| Shaping | Utilizes various dies to form intricate shapes in metal sheets. | Used in manufacturing parts like auto panels and custom fixtures. | Aluminum, Steel, Copper |

| Punching | Creating holes in sheet metal using a punch and die set. | Essential for parts that require fastening or weight reduction. | Steel, Aluminum, Brass |

Quality control is vital in sheet metal work. It ensures that the final product meets both safety and performance standards. Accurate measurements are crucial. Even a minor mistake can lead to significant issues. Regularly checking dimensions can save time and resources. Maintain a checklist for routine inspections.

Tips: Use calipers for precise measurements. Always double-check your work. A second set of eyes can catch errors you may miss. Documentation helps maintain consistency and traceability.

Different materials behave differently. For instance, aluminum may expand more than steel. Adjust measurements accordingly to account for these variations. Ignoring material properties can lead to failure. Make samples and test them before full production. This step is too often overlooked.

Tips: Keep a log of your quality checks. This can reveal patterns or persistent mistakes. Investing time in quality control pays off in the long run.

You are using an outdated browser. Things may not appear as intended. We recommend updating your browser to the latest version.

Close