Sand casting is a fascinating yet challenging metalworking technique. Renowned expert John Smith once said, "Mastering sand casting is vital to achieving high-quality metal components." This quote captures the essence of what it takes to excel in this craft.

In sand casting, practitioners create molds using sand mixed with a binder. This process allows for intricate designs and shapes. However, mastering the technique is not easy. Many beginners struggle with achieving precise mold shapes. Imperfections may result in flawed castings. Learning from these mistakes is crucial for progress. The journey requires patience and practice.

Sand casting offers endless possibilities. Yet, it's not without its challenges. Fine-tuning the mixture of sand can significantly impact results. Observing details, like temperature and pour rates, also matters. Each step can make or break a casting. Acknowledging these pitfalls can enhance skill levels and lead to better outcomes.

Sand casting is a time-honored technique in metalworking, renowned for its versatility. It utilizes a mixture of sand, clay, and water to form molds. According to industry reports, about 70% of foundries use sand casting due to its cost-effectiveness and adaptability. The process allows for the creation of intricate designs and large parts, meeting diverse manufacturing needs.

The materials used in sand casting significantly influence the outcome. Silica sand is the primary component. However, the quality of the clay binder and the water content are equally crucial. Engineer reports indicate that improper ratios can lead to defects, affecting the durability of the castings. The importance of understanding the interaction between materials cannot be overstated.

While many professionals excel in basic techniques, mastering sand casting involves ongoing learning. Even experienced craftsmen encounter challenges, such as sand deformation and poor surface finish. Continuous testing and refinement are essential. Engaging with modern technologies can also improve results, blending tradition with innovation. This hybrid approach may reduce waste and enhance efficiency in the long run.

This chart illustrates the influence of different factors on the quality of metalwork in sand casting techniques. The data reflects the relationship between the percentage of various parameters and the resulting quality rating in metal casting.

When diving into sand casting, having the right tools and equipment is crucial. The essentials include a sand mixture, patterns, and molds. A quality sand mixture often consists of silica sand, clay, and water. Industry reports indicate that a well-balanced mixture enhances mold strength, leading to better castings. The addition of clay helps binding; too much can make molds brittle, causing defects.

Molds play a significant role too. Metal patterns are often preferred for durability but are costlier. On the other hand, wood is cheaper but may warp or swell. Precision is key. Even minor flaws in molds can lead to major casting errors. Reports have shown that nearly 30% of casting defects are due to poor mold quality. Maintaining and inspecting your tools is just as important. Regular wear can go unnoticed, leading to inconsistent results.

Additionally, tools like a furnace and pouring equipment must be considered. These need to be maintained for safety and efficiency. A poorly calibrated furnace can alter metal temperatures, affecting the final product. Keeping a checklist for equipment maintenance can help avert potential mishaps. Familiarity with these aspects enables a smoother casting process, though it requires continuous reflection and adjustment in techniques.

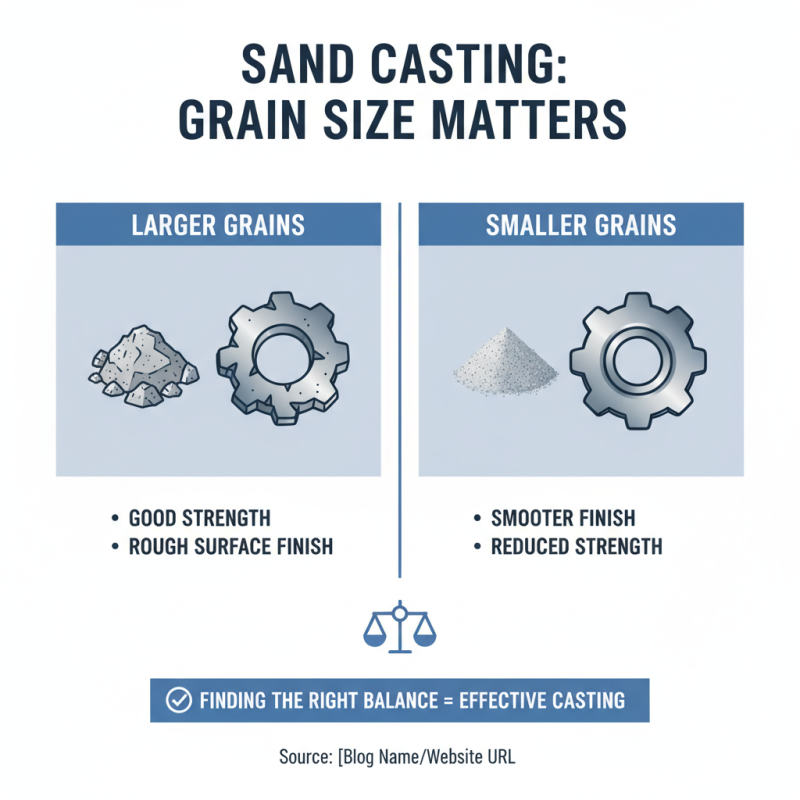

In sand casting, understanding sand composition is essential. Grain size significantly influences the final metal product's quality. Larger grains provide good strength but can lead to rough surfaces. Smaller grains result in smoother finishes but may sacrifice strength. Finding the right balance is crucial for effective casting.

Bonding agents play a pivotal role in sand casting. They help grains stick together, forming a solid mold. Common agents include clay, which enhances the mold's integrity. However, overusing bonding agents can lead to defects. It's important to experiment to achieve optimal results.

**Tips:** Always test your sand with different additives. Keep track of how they affect your work. Regularly assess your molds' performance. If something fails, reflect on the grain size and bonding ratio. A small change can yield significant improvements. Don't shy away from adjusting your methods. Experimentation is key to mastering sand casting.

Creating high-quality sand molds requires careful attention to detail. Start by selecting the right type of sand. Fine particle size often leads to better mold detail. According to industry reports, using compacted green sand can significantly improve mold strength. This type of sand retains moisture, which enhances its binding properties.

Next, focus on the molding process. Ensure that your sand is evenly mixed. Use a mold box to maintain shape. Many experts suggest that mold thickness should be at least one inch. This thickness helps prevent breakage during casting. Even with the best materials, expect some imperfections. Air pockets or uneven surfaces can occur. Reflecting on these flaws can lead to better results.

Once the mold is created, it’s essential to allow it to cure. Insufficient curing may lead to mold failure. Studies show that proper drying times improve the outcome of the cast. Evaluate each casting. Learn from mistakes. Documenting issues can refine your techniques in future projects. Remember, mastery is a continuous journey.

Sand casting is a widely used technique for producing metal components. However, common defects can arise during the process. Identifying these issues is crucial to enhance the final product's quality.

One frequent problem is the presence of sand inclusions. These occur when sand particles become trapped in the metal, which can weaken the structure and affect the appearance. To mitigate this, ensuring proper mold preparation is vital. A clean, well-maintained mold can prevent contamination.

Another common defect is shrinkage cavities. These happen when molten metal cools and contracts too quickly. They often appear in thicker sections, leading to weak spots. To combat this, consider optimizing the design by adding risers or using insulated materials.

These adjustments can help achieve a uniform cooling rate and minimize defects. Regular inspection and adjustment of techniques are essential for improving outcomes in sand casting.

You are using an outdated browser. Things may not appear as intended. We recommend updating your browser to the latest version.

Close