Sand casting is a time-honored manufacturing process that has been utilized for centuries to create intricate metal components. This versatile technique involves creating a mold from sand, which can then be filled with molten metal to produce a wide variety of solid parts. Understanding the fundamentals of sand casting is essential for anyone looking to master this craft, whether for professional purposes or as a hobby. In this guide, we will delve into ten essential tips that will help you refine your sand casting techniques and achieve more precise results.

From selecting the right materials to optimizing the molding process, each aspect of sand casting plays a crucial role in the overall outcome. Through careful attention to detail and a willingness to learn from each pour, practitioners can significantly enhance their mastery of sand casting. By embracing these tips, you will not only improve your casting quality but also develop a deeper appreciation for this intricate art form. Join us as we explore the essential strategies for mastering sand casting, and unlock the potential of this incredible metalworking technique.

Sand casting is a versatile manufacturing process that involves creating metal parts through the use of sand molds. At its core, the technique requires an understanding of several key concepts and terminology. The primary components of sand casting include the mold, core, and metal alloy. The mold is formed from a mixture of sand and a binding agent, which holds the shape when the molten metal is poured into it. Cores are used to create internal features and are made from a similar sand mixture, sometimes coated with a release agent to ensure easy removal after the casting process.

It is also essential to grasp the importance of gating systems and risers, which play a crucial role in the flow of molten metal. The gating system directs the metal into the mold, while risers act as reservoirs that supply additional metal to compensate for shrinkage during cooling. Understanding these elements is fundamental for achieving high-quality castings, as they influence material flow, cooling rates, and overall dimensional accuracy. Mastery of sand casting demands not only knowledge of these key concepts but also practical experience in mold preparation, metal pouring, and post-casting finishing techniques.

| Tip Number | Tip Description | Key Concept |

|---|---|---|

| 1 | Choose the right sand mixture for desired properties. | Sand Composition |

| 2 | Ensure proper mold design for effective pouring. | Mold Architecture |

| 3 | Optimize casting temperature for material used. | Temperature Control |

| 4 | Use proper pouring techniques for minimal defects. | Pouring Method |

| 5 | Implement effective cooling practices to reduce defects. | Cooling Strategies |

| 6 | Incorporate proper venting to allow air escape. | Venting Systems |

| 7 | Regularly inspect and maintain equipment. | Equipment Maintenance |

| 8 | Conduct tests to ensure sand quality and consistency. | Quality Control |

| 9 | Use additives to enhance sand properties. | Additive Usage |

| 10 | Train staff on best practices and safety measures. | Training and Safety |

When it comes to mastering sand casting techniques, selecting the right sand medium is crucial for achieving quality results. Sand casting typically utilizes two primary types of sand: green sand and resin-bonded sand. Green sand is a mixture of silica sand, clay, and moisture, making it the most commonly used medium due to its cost-effectiveness and favorable properties. According to industry analyses, green sand accounts for approximately 90% of the sand used in metal castings, making it a staple for foundries worldwide. Its ability to retain moisture allows for excellent mold strength and helps in producing intricate designs.

On the other hand, resin-bonded sands, which are cured by heat and include a variety of resins, offer superior surface finishes and precision. While they represent a smaller segment of the market, recent reports indicate a growing trend towards their use due to advancements in technology that increase their performance in high-temperature applications. When selecting a sand medium, it is essential to consider factors such as the type of metal being cast and the complexity of the mold. For example, when working with aluminum, many professionals recommend using a fine-grade sand for improved detail.

Tip: Always conduct tests with your selected sand to gauge its compatibility with your casting materials and patterns. Implementing a controlled approach to sand quality, such as regular testing for grain size and bonding properties, can lead to enhanced production outcomes and reduced scrap rates. Additionally, keep an eye on industry reports to stay informed about innovations in sand types and their properties, as they can significantly impact your casting projects and efficiency in the foundry.

Creating effective mold patterns and cores is crucial in sand casting, as it directly influences the quality and accuracy of the final product. The first step in mastering this technique is to select the right pattern material. Common choices include wood, metal, or plastic, each offering distinct advantages. For instance, wood is easy to work with for intricate designs, while metal patterns can provide durability for high-volume production runs. Whichever material you choose, ensure the pattern is designed with proper shrinkage allowances to accommodate the natural changes that occur during cooling.

In addition to material choice, precise pattern design plays a significant role. Incorporating features like draft angles allows for easier removal from the mold without damaging the pattern. Moreover, designing cores to fill internal cavities requires careful consideration of the core sand properties. Using a high-quality core sand mixture will result in better strength and stability, minimizing the risks of deformation during the casting process. Finally, ensuring a proper fit between the pattern and the core can prevent defects, ultimately leading to a smoother production cycle and reducing the need for costly rework.

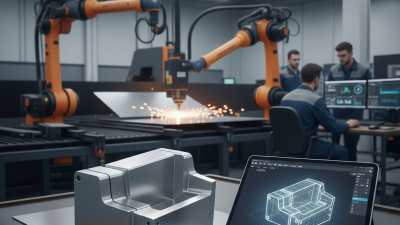

Mastering the pouring process in sand casting is crucial for achieving high-quality castings. One of the best practices involves ensuring that the temperature of the molten metal is optimal before the pour. This means closely monitoring the melt process and maintaining a consistent temperature to prevent defects such as cold shuts or misruns. Additionally, it’s important to use a well-designed pouring cup that allows for a smooth flow of metal into the mold. A runner system should be strategically designed to minimize turbulence, which can introduce air bubbles and other contaminants into the casting.

Another key technique is controlling the pour rate. A slow and steady pour helps achieve better fill and reduces the risk of defects. It’s essential to pour from a height and angle that avoids splashing while ensuring that the metal reaches all areas of the mold without leaving voids. Moreover, timing plays a significant role; keeping the pour time consistent helps maintain the integrity of the mold. By employing these tips, practitioners can enhance their pouring techniques, leading to efficient mold filling and superior casting quality.

Cleaning and inspecting sand casted parts are crucial steps in the sand casting process, ensuring that the final product meets quality and performance standards. After the casting has cooled and solidified, it's essential to remove any excess sand and residue using a combination of mechanical and manual cleaning methods.

This might involve using wire brushes, air blowers, or even shot blasting to remove any remaining mold materials. Care should be taken not to damage the surface of the casting in this process.

Following the cleaning, thorough inspection is vital to identify any defects such as cracks, porosity, or dimensional inaccuracies. Employing techniques like visual inspections or utilizing advanced methods such as dye penetrant testing can unveil issues that might not be visible to the naked eye. Proper documentation of any findings is important to ensure each component meets the outlined specifications and contributes to the overall integrity of the final product.

One essential tip is to implement a systematic approach to both cleaning and inspection. Developing checklists and standardized procedures can greatly enhance the consistency of these processes. Additionally, maintaining a clean and organized workspace helps facilitate effective cleaning and inspection, reducing the risk of overlooking critical defects. Regular training sessions for the team on best practices can further ensure that high-quality standards are maintained throughout the production cycle.

You are using an outdated browser. Things may not appear as intended. We recommend updating your browser to the latest version.

Close