In the fast-paced world of manufacturing, the development of a sheet metal prototype plays a crucial role in the rapidly evolving landscape of product design and production. According to a recent report by IBISWorld, the sheet metal fabrication industry is projected to grow by 3.5% annually, reflecting an increased demand for prototypes that streamline production processes and reduce costs. This growing trend emphasizes the necessity for manufacturers to adopt efficient methods in creating sheet metal prototypes to remain competitive in the market.

Industry experts, such as Dr. Emily Chen, a leading voice in the engineering design sector, highlight the significance of optimizing prototype creation. Dr. Chen recently stated, "The key to reducing costs while maintaining quality in sheet metal prototypes lies in utilizing advanced software tools and methods that enhance precision and speed." Her insights underline the importance of integrating technology with traditional fabrication techniques, enabling businesses to deliver high-quality prototypes that meet customer needs without breaking the bank.

As innovative technologies continue to reshape the field, understanding the best practices for creating a sheet metal prototype not only aids in accelerating time-to-market but also contributes to financial efficiency. This article aims to explore various strategies and tools that can be applied to facilitate the effective and cost-efficient development of sheet metal prototypes, ensuring that manufacturers can meet the demands of a dynamic market.

When embarking on the journey of sheet metal prototyping, understanding the fundamental principles of the process is essential. Sheet metal prototyping involves creating physical models of parts or products from flat sheets of metal, which subsequently undergo cutting, bending, and assembling. The industry has witnessed a 15% increase in demand for rapid prototyping solutions over the past five years, indicating a growing recognition of its value in product development.

One effective tip for ensuring efficiency during prototyping is to utilize advanced software tools that allow for precise designs and calculations. Programs like CAD (Computer-Aided Design) not only streamline the design phase but also help in minimizing material wastage—reportedly, poor design can lead to up to 30% excess material usage. Selecting the right thickness for your sheet metal according to the final product's requirements can significantly reduce costs and lead times.

Another critical aspect of cost-effectiveness in sheet metal prototyping is to embrace automation wherever possible. Automated cutting and bending machines can improve both speed and accuracy, which, according to a recent report from the Fabricators & Manufacturers Association, can reduce overall production time by 50%. Investing in training for your team to adeptly use these technologies can further enhance productivity and ensure high-quality outputs in your prototyping endeavors.

When creating sheet metal prototypes, selecting the right materials is crucial for balancing cost-effectiveness and functionality. According to recent industry reports, the material choice significantly impacts both production costs and the overall performance of the prototypes. For instance, aluminum and stainless steel are two popular options in prototyping, with aluminum being lighter and more affordable, typically costing between $1.00 to $3.00 per pound, compared to stainless steel, which can range from $2.00 to $4.50 per pound. Additionally, the inherent properties of aluminum, such as corrosion resistance and ease of machining, make it an excellent choice for many applications, thus optimizing both manufacturing processes and budget management.

Furthermore, advancements in additive manufacturing materials are transforming traditional prototyping methods. Recent explorations into polymer and metal powders indicate that these materials offer enhanced design flexibility and quicker turnaround times, which are vital for maintaining competitiveness in a rapidly evolving market. The integration of new materials not only accelerates prototyping but also allows for more complex designs that were previously unfeasible. This shift proves that continuously assessing and updating material selections is key to achieving cost-effective solutions while meeting stringent production quality standards.

When creating a sheet metal prototype, having the right tools and equipment is crucial for both efficiency and cost-effectiveness. Essential tools include CNC machines, which enhance precision and reduce waste; laser cutters for intricate designs; and bending brakes for shaping metal accurately. According to a report by Grand View Research, the global sheet metal fabrication market is projected to reach USD 304.25 billion by 2025, highlighting the growing demand for advanced fabrication technologies.

Moreover, investing in high-quality machinery can drastically decrease prototyping time. A study published by Manufacturing.net notes that companies adopting automated solutions in their sheet metal operations see a productivity increase of 30% to 50%. This shift not only streamlines the fabrication process but also allows for faster iteration cycles in product development, enabling businesses to respond to market demands more swiftly. By equipping workshops with state-of-the-art tools, manufacturers can optimize their production processes, ultimately leading to significant cost savings and improved output quality.

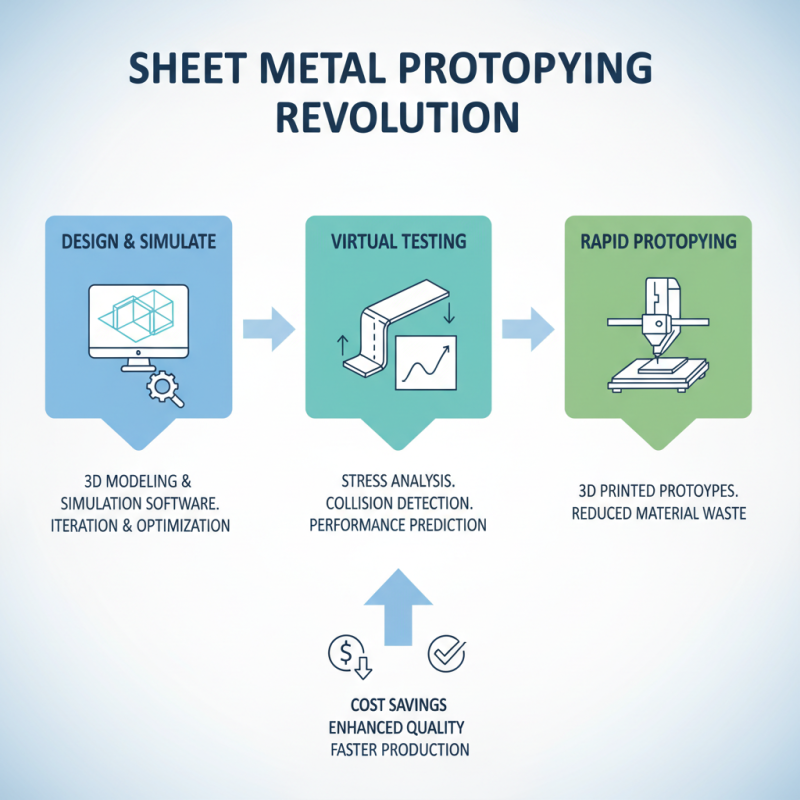

In today's fast-paced manufacturing environment, the adoption of 3D simulation and printing software is crucial for efficiently designing and producing sheet metal prototypes. Utilizing advanced 3D modeling solutions allows teams to iterate, test, and optimize designs before going into production. This iterative process helps identify potential issues during the design phase, ultimately enhancing product quality and reducing costs. By simulating various scenarios, designers can ensure their prototypes meet required specifications, facilitating smoother transitions to actual production.

**Tips for Efficient Design:**

- Embrace 3D simulation tools to visualize prototypes in real-time, which can lead to better decision-making early in the design process.

- Implement rapid prototyping techniques using 3D printing to quickly produce and test physical models, saving both time and resources.

Furthermore, the growth of the 3D printing market highlights its role in revolutionizing prototype production. The market for 3D printed medical device prototypes is projected to grow significantly, reaching $1.8 billion by 2034. As industries increasingly recognize the benefits of 3D printing, they are likely to leverage this technology for producing innovative products, leading to more efficient and cost-effective manufacturing processes.

Testing and iterating your sheet metal prototype is crucial for ensuring that the final product meets design specifications and performs reliably under real-world conditions. According to a report by the **American Society of Mechanical Engineers (ASME)**, over 70% of manufacturing issues can be traced back to flaws found during the prototyping phase. Therefore, incorporating a rigorous testing framework that includes stress tests, fatigue analysis, and compliance with industry standards is essential. Use of advanced testing technologies like digital twin simulations can help predict performance and lifecycle, allowing for adjustments to be made before physical prototypes are created.

Moreover, iteration should not be seen as a burden but rather as an opportunity for innovation. A study from the **National Institute of Standards and Technology (NIST)** indicates that manufacturers who embrace an iterative design approach can reduce time-to-market by up to 40%. By leveraging rapid prototyping techniques, such as laser cutting and 3D printing, designers can quickly create variations of their initial prototype, facilitating faster feedback loops. This agile methodology allows teams to gather real-time data from testing, fostering an environment where continuous improvement is not just possible but also expected. Ultimately, embracing these practices will lead to a more refined product and higher customer satisfaction.

| Prototype Stage | Description | Materials Used | Cost Estimate ($) | Time Required (days) | Testing Method | Feedback Outcome |

|---|---|---|---|---|---|---|

| Initial Concept Prototype | Basic design to visualize the idea. | Cardboard and 3D printed components | 150 | 5 | Visual Inspection | Positive feedback on design concept. |

| Functional Prototype | Prototype with moving parts for testing functionality. | Aluminum and plastic | 500 | 10 | Functional Testing | Needed adjustments for stress points. |

| Final Prototype | Final adjustments made for production. | Stainless Steel | 800 | 15 | Endurance Testing | Met all specifications successfully. |

| Pre-Production Prototype | Ready for small scale production testing. | Cold Rolled Steel | 1200 | 20 | Market Testing | Excellent user feedback for usability. |

You are using an outdated browser. Things may not appear as intended. We recommend updating your browser to the latest version.

Close