Choosing the right precision CNC machining service for your project is crucial. The process involves intricate details. Each project demands specific needs and requires thoughtful consideration.

Precision CNC machining offers accuracy and consistency. However, it is not always the simplest choice. Understanding your requirements is key to making a wise selection. Sometimes, the most advanced machines may not suit every task. Evaluating your materials and designs is essential.

There are various providers out there, and not all are equal. Some might promise perfection but fall short. It is important to consider factors like experience, equipment, and customer feedback. The right choice can lead to high-quality results, while a poor decision may cause setbacks. Reflecting on your options can make a significant difference.

Precision CNC machining stands at the forefront of modern manufacturing. It allows for the creation of highly detailed parts with exceptional accuracy. This technology is utilized across various industries, from aerospace to medical devices. The ability to produce intricate geometries makes it essential for projects demanding high precision.

Applications of precision CNC machining are diverse. In the automotive industry, CNC machines fabricate components that ensure vehicle safety and performance. In electronics, they create intricate housings and connectors. Each application requires careful consideration of materials and tolerances. However, not every project may benefit from CNC machining. Some might require a simpler approach. It's essential to assess project needs thoroughly before deciding.

Choosing precision CNC machining requires reflection. Consider whether the project truly needs such high precision. In some cases, softer machining methods may suffice. Evaluating the project's specifications is crucial. This process can lead to cost savings and a quicker turnaround. Don't rush into CNC machining without fully understanding its implications for your project.

When selecting precision CNC machining, understanding your project requirements is crucial. Start by determining the material you need. Metals, plastics, and composites each have unique properties. Consider the weight, strength, and durability required for your application. This decision will significantly affect the machining process.

Next, think about the tolerances your project demands. Are tight tolerances necessary, or can you allow more leeway? Knowing this will guide you to the right machinery and techniques. Also, assess the volume of parts required. High production runs may benefit from different methods compared to single prototypes. Don’t forget to factor in lead times. A rushed timeline can compromise quality and increase costs.

Finally, reflect on your budget. Do not overlook potential hidden costs. Sometimes, cheaper options can lead to more expenses down the line. Ensure you’re considering both initial and long-term costs. This proactive approach helps in making informed decisions, ensuring that all facets of your project are adequately addressed.

When selecting materials for CNC machining, precision matters. Common choices include aluminum, steel, and plastics. According to a 2021 industry report, aluminum accounts for about 60% of CNC machined parts in aerospace applications. This is due to its lightweight nature and strong resistance to corrosion. However, choosing aluminum isn't always straightforward. Material cost and machinability can vary significantly.

Steel is another popular option, especially for heavy-duty applications. It offers excellent strength, making it suitable for structural components. However, it's crucial to note that some steel grades can be challenging to machine effectively, leading to longer production times and increased costs. For example, high-carbon steels are more robust but often require more complex machining strategies.

Plastics, like polycarbonate and nylon, provide unique benefits for specific projects. These materials are often lightweight and corrosion-resistant. However, their heat sensitivity can pose challenges during machining. A substantial portion of failed CNC projects can be attributed to unsuitable material choices. Rethinking material specifications is essential to avoid these pitfalls and ensure project success. Each project demands careful evaluation of material properties to yield the desired precision and durability.

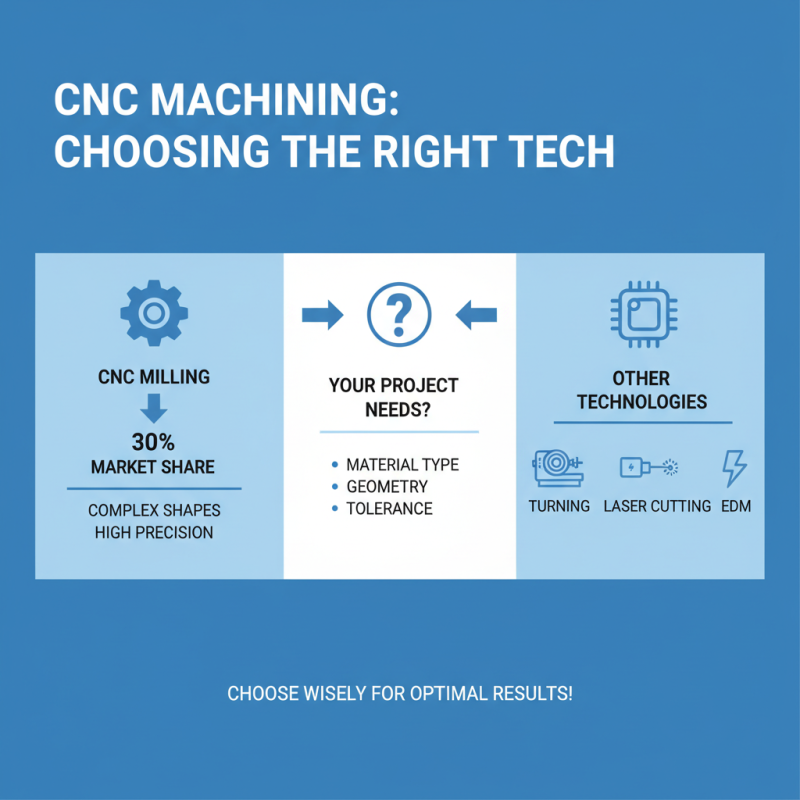

Choosing the right CNC machining technology is crucial for any project. Different technologies cater to varying needs. For instance, Computer Numerical Control (CNC) milling remains popular. According to industry reports, CNC milling accounts for nearly 30% of the total CNC machining market. This is due to its ability to produce complex shapes with high precision.

However, CNC turning is also worth considering. It excels in producing cylindrical parts with excellent surface finishes. A recent survey indicated that about 22% of manufacturers prefer CNC turning for its efficiency and accuracy. Each technology has its strengths and weaknesses. Sometimes, a project’s requirements can overlap, leading to confusion. Not every project fits neatly into a specific category.

Material choice can complicate matters. Some CNC processes work better with metals, while others suit plastics. According to research, around 40% of project delays are linked to material selection. Thus, having a clear understanding of the project's goals is essential. It helps in selecting the appropriate CNC technology. Each choice involves trade-offs that need careful consideration.

When selecting a precision CNC machining service, quality control is paramount. A recent report from a leading industry analysis firm indicates that nearly 30% of projects face delays due to inadequate quality measures. It's critical to assess a manufacturer’s quality control protocols before partnering with them. Look for certifications like ISO 9001 that demonstrate commitment to high standards.

Tip: Always request documentation of their quality assurance processes. This can include inspection reports, testing methods, and traceability systems. Effective measures can significantly reduce defects, ensuring a smoother production process.

CNC machining technology has advanced, yet quality issues still arise. The report highlights that up to 15% of machined products do not meet specifications. Regular audits and employee training programs can help mitigate this risk. Companies should prioritize transparency in their operations to foster trust.

Tip: Inquire about their corrective action plans. Understanding how they respond to quality failures can reveal their reliability. A proactive approach to quality control contributes to project success, minimizing waste and unexpected costs.

| Criteria | Description | Importance Level | Assessment Method |

|---|---|---|---|

| Material Quality | Evaluating the raw materials used in CNC machining. | High | Material certificates and testing reports. |

| Machine Calibration | Regular calibration of CNC machines to ensure accuracy. | High | Calibration logs and procedures. |

| Tool Management | Monitoring and maintaining cutting tools to prevent wear. | Medium | Tool life tracking and replacement logs. |

| Quality Inspections | Systematic inspections during and post-production. | High | Inspection reports and quality audits. |

| Process Documentation | Detailed documentation of CNC machining processes. | Medium | Process descriptions and workflow diagrams. |

You are using an outdated browser. Things may not appear as intended. We recommend updating your browser to the latest version.

Close