In the ever-evolving landscape of manufacturing, plastic injection molding stands out as one of the most widely employed techniques for producing intricate and repeatable plastic parts. According to a report by MarketsandMarkets, the global plastic injection molding market is projected to reach USD 453.6 billion by 2027, highlighting its significance in various sectors including automotive, consumer goods, and healthcare. This substantial growth underscores the necessity for manufacturers to adopt best practices in order to optimize their processes, reduce production costs, and enhance product quality.

As competition intensifies and consumer demand for precision increases, the optimization of plastic injection molding processes becomes critical. Implementing effective strategies not only improves operational efficiency but also contributes to sustainability goals by reducing waste and energy consumption. A comprehensive industry analysis indicates that even minor enhancements in the injection molding process can lead to significant improvements in output and performance metrics. The following guidelines will explore ten best practices that can serve as a roadmap for manufacturers seeking to refine their plastic injection molding operations, ultimately leading to smarter production choices and increased profitability.

Plastic injection molding is a cornerstone manufacturing process widely used in various industries, including automotive, consumer goods, and medical devices. This technique involves injecting molten plastic into a mold to create intricate shapes and components with exceptional precision. According to the 2021 Plastics Industry Association report, the global plastic injection molding market is expected to grow significantly, reaching USD 407.5 billion by 2027, illustrating its fundamental role in modern production.

One important aspect of plastic injection molding is its efficiency in producing high volumes of parts with minimal waste. The process can achieve cycle times as low as 15 seconds for certain applications, enhancing productivity and reducing operational costs. A study from the Society of Plastics Engineers reveals that nearly 80% of plastic parts produced globally utilize injection molding, emphasizing the technology's dominance. Furthermore, optimizing parameters such as temperature control, injection speed, and mold design can lead to improved consistency and quality of the final products, making it an essential focus for manufacturers looking to stay competitive in the evolving market landscape.

| Best Practice | Description | Benefits |

|---|---|---|

| Optimize Cooling Time | Adjust cooling channels and temperatures for efficient heat removal. | Reduces cycle time, increases production efficiency. |

| Material Selection | Choose the right plastic material for specific applications. | Improves product strength and reduces waste. |

| Mold Design Optimization | Refine mold geometry for better material flow. | Enhances product quality and consistency. |

| Implement Process Monitoring | Use sensors to track injection molding parameters. | Enables early detection of issues, reducing scrap rates. |

| Regular Maintenance | Schedule periodic checks on machines and molds. | Prevents downtime and extends equipment lifespan. |

| Control Injection Pressure | Adjust pressure settings for optimal filling. | Minimizes defects like warping and short shots. |

| Use Simulation Software | Model the injection process virtually before actual production. | Identifies potential issues, saving time and costs. |

| Training and Skill Development | Provide ongoing training for staff involved in molding processes. | Enhances operational efficiency and reduces errors. |

| Sustainability Considerations | Explore biodegradable materials and recycling methods. | Promotes eco-friendly practices and reduces environmental impact. |

The injection molding process is significantly influenced by various key factors that can determine the efficiency and quality of the final product. One crucial aspect is the material selection, as different plastics have unique flow characteristics, thermal properties, and shrinkage rates. Understanding the behavior of the chosen material during melting, cooling, and solidification stages is vital for achieving optimal results. Additionally, the moisture content of the resin can greatly affect the molding process; excessive moisture can lead to defects, such as bubbling or poor surface finish, which underscores the necessity for adequate drying before processing.

Another important factor is the design of the mold itself. Proper mold design features, such as gate placement, cooling channel configuration, and venting systems, play a significant role in controlling the filling pattern and thermal distribution during injection. An efficient cooling system reduces cycle times and enhances dimensional accuracy, while effective venting prevents trapped air that can cause defects. Furthermore, the machine parameters, including injection speed, pressure, and temperature, must be meticulously calibrated to match the specific requirements of the chosen material and mold design to ensure a smooth and successful production process.

This chart illustrates the key factors influencing the plastic injection molding process and their respective impacts based on industry surveys.

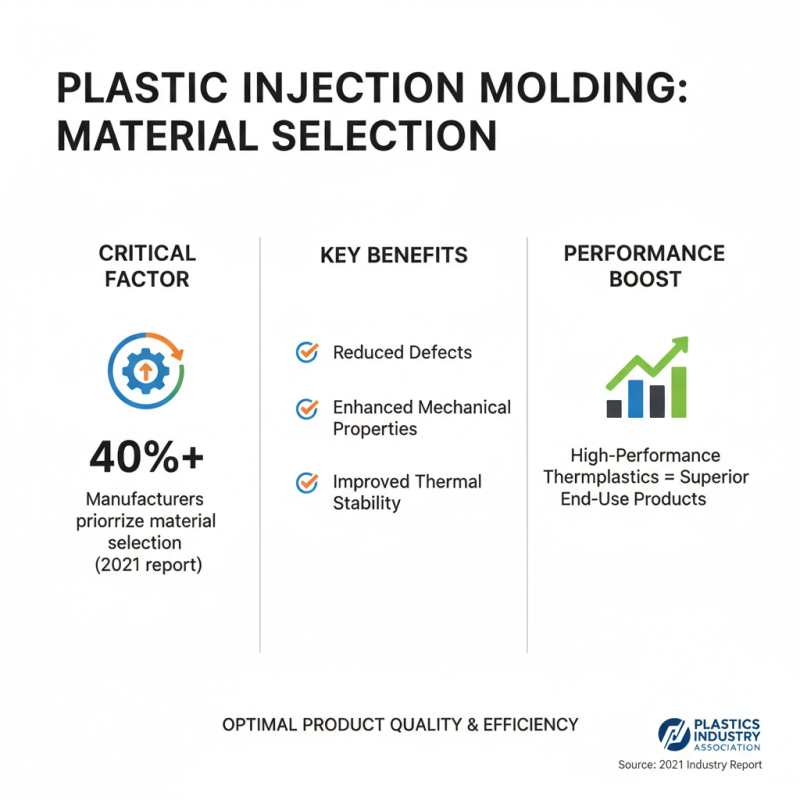

The selection of materials in plastic injection molding is critical for achieving optimal product quality and performance. According to a 2021 report by the Plastics Industry Association, over 40% of manufacturers cite material selection as a crucial factor that influences their production efficiency and product durability. Selecting the right polymer can reduce defects, enhance mechanical properties, and provide improved thermal stability. For example, using high-performance thermoplastics can lead to significant performance enhancements in end-use applications, reducing the need for costly post-processing.

Moreover, quality assurance during the material selection process cannot be overlooked. A comprehensive study by the Society of Plastics Engineers found that nearly 25% of defects in molded parts stem from improper material use. This underlines the importance of conducting thorough testing and validation of materials before production begins. Implementing stringent quality control measures and adhering to material specifications can not only mitigate risks but also ensure consistency in output. By utilizing advanced material properties data and simulation technologies, manufacturers can make informed decisions that ultimately lead to higher quality products and reduced waste in the injection molding process.

Plastic injection molding is a widely used manufacturing process valued for its efficiency, but optimizing it can yield significant advantages in cycle time and waste reduction. Industry reports indicate that improving cycle time by just 10% can lead to a decrease in production costs by up to 20%. Techniques such as process integration, which involves simultaneous design and production planning, enable manufacturers to streamline operations and reduce idle time during production phases. Data from the Society of Plastics Engineers underscores that by adopting automation in material handling, manufacturers can further enhance cycle efficiency, ultimately translating to reduced energy consumption and lower operational costs.

Waste reduction is another critical aspect of plastic injection molding optimization. According to a report from the American Society of Plastic Engineers, implementing advanced quality control measures can decrease scrap rates by approximately 15%-25%. Techniques like in-process monitoring and the use of simulation software to predict mold performance are essential in identifying potential issues before they escalate. Additionally, recycling scrap materials not only minimizes waste but also contributes to a circular economy within the plastics industry, enhancing sustainability. Leveraging these best practices not only improves overall efficiency but also positions manufacturers at the forefront of eco-friendly production methods.

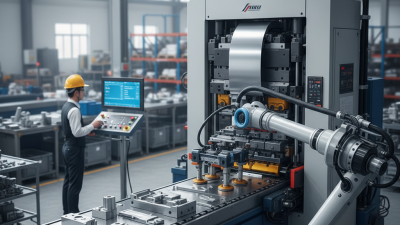

Recent advancements in technology have significantly transformed plastic injection molding operations, enhancing efficiency and reducing costs. Innovations such as advanced simulation software are now facilitating more accurate modeling and analysis of the injection process. According to a report from The Freedonia Group, the global market for plastic injection molding is expected to reach $360 billion by 2025, driven by continuous enhancements in machine design and materials. These technologies enable manufacturers to optimize cycle times, reduce scrap rates, and improve product quality, showcasing the substantial return on investment achievable through modernized operations.

Additionally, the integration of artificial intelligence and machine learning into injection molding processes is revolutionizing production. By utilizing big data analytics, manufacturers can predict maintenance needs, thereby minimizing downtime. A study from Grand View Research indicates that automation in manufacturing processes can lead to productivity increases of up to 40%. Furthermore, the adoption of Industry 4.0 principles allows for real-time monitoring and process adjustments, leading to improved efficiency and sustainability across production lines. This evolution in technology is pivotal, positioning companies to meet the rising demands for faster turnaround times and superior product standards in an increasingly competitive marketplace.

You are using an outdated browser. Things may not appear as intended. We recommend updating your browser to the latest version.

Close